Engineer at the University of Houston develops improved, biodegradable, multifunctional bacterial cellulose sheets with the potential to replace plastics in multiple industries. The goal is to replace petroleum-based materials that do not degrade. Potential applications include green electronics, energy storage, sustainable packaging, and smart textiles, among others.

- Bacteria produce biodegradable cellulose.

- New technique: controlled rotation to align fibres.

- Boron nitride nanolayers are added.

- Result: strong, flexible and transparent material.

- Potential replacement for plastic, packaging, textiles, green electronics.

- Up to 553 MPa tensile strength.

- 3 times better heat dissipation.

- Scalable and low environmental impact technology.

University of Houston develops a possible replacement for plastic

Enhanced bacterial cellulose for strong, eco-friendly everyday materials

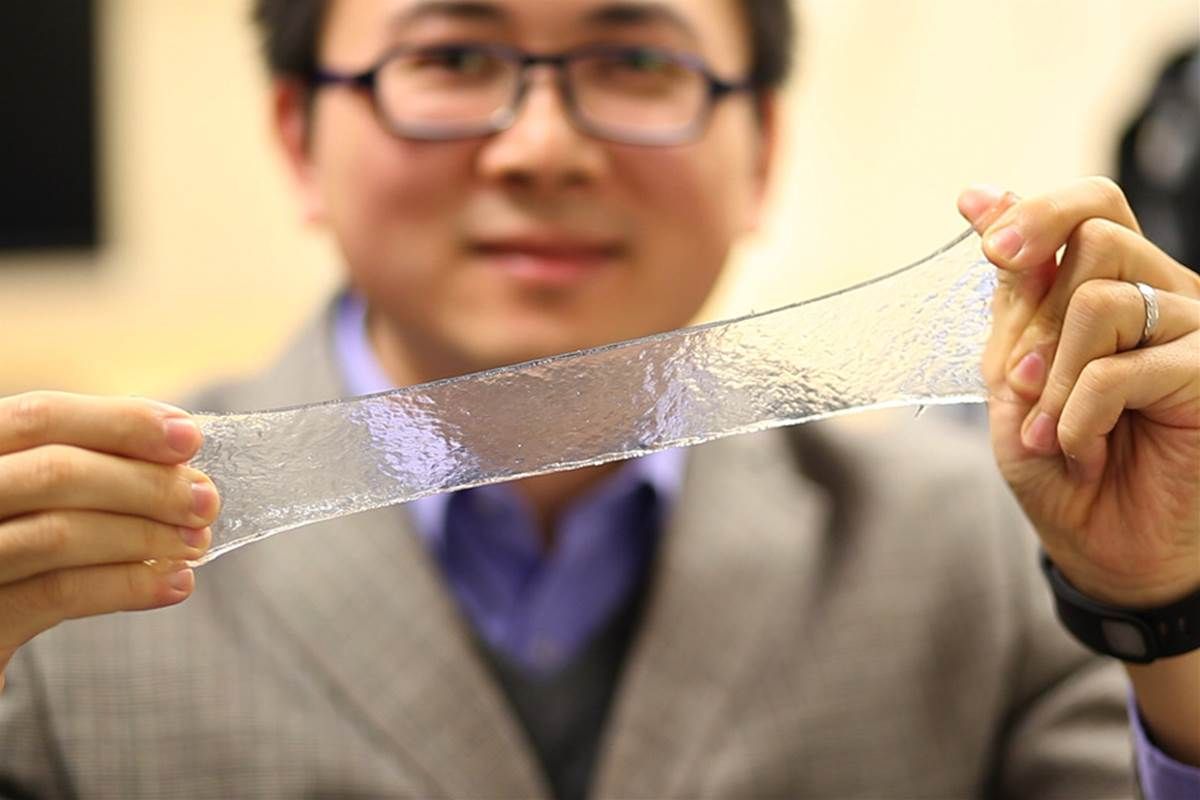

In response to the serious global problem of plastic pollution, Assistant Professor Maksud Rahman of the University of Houston has developed a new way to manufacture bacterial cellulose with significantly improved mechanical and functional properties. This modified cellulose has the real potential to replace plastics in a variety of everyday applications, from packaging to textiles and electronic devices.

What is bacterial cellulose?

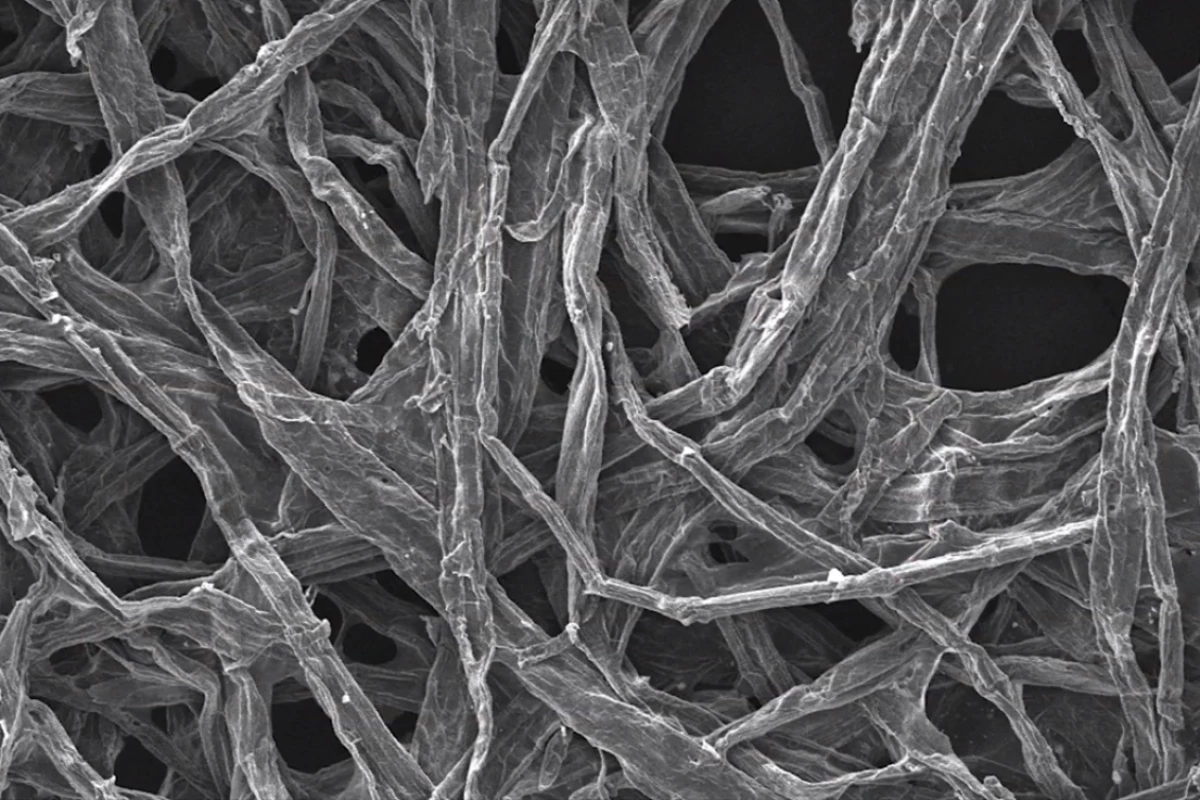

Bacterial cellulose is a natural, biodegradable and biocompatible biopolymer produced by bacteria such as Komagataeibacter xylinus. Unlike plastic, it does not come from petroleum and does not generate persistent waste in the environment.

However, its mechanical weakness and limited functionality had prevented its widespread use… until now.

Technological innovation: alignment of nanofibres using rotational flow

Rahman’s team introduced a rotational culture system, where cellulose-producing bacteria are grown in a constantly rotating oxygenated cylinder. This rotation creates a directional flow of liquid, forcing the bacteria to move in an orderly fashion.

The result?

A cellulose structure with aligned nanofibres, which significantly improves its strength, flexibility and mechanical stability.

Reinforcement with nanomaterials: boron nitride

To take this a step further, the researchers added boron nitride nanolayers to the culture medium. The result was a hybrid material with:

- Tensile strength of up to 553 MPa.

- Optical transparency.

- Long-term mechanical stability.

- Three times more efficient heat dissipation than unmodified cellulose.

These properties open the door to applications in thermal management, structural materials, green electronics, technical textiles and more.

A simple, scalable and sustainable process

One of the biggest advantages of Rahman’s approach is its scalability. It is a single-step biotechnological process that does not require toxic chemicals or extreme conditions.

The system allows the properties of the material to be adjusted by modifying the culture conditions or the added nanomaterials. In other words, the final product can be customised according to the desired application.

Potential of this technology

This advance has a direct impact on the fight against plastic. Thanks to its natural origin, biodegradability and high performance, enhanced bacterial cellulose could replace synthetic polymers in key sectors:

- Biodegradable packaging for food, beverages and consumer products.

- Sustainable textiles with technical properties.

- Green electronics with better thermal management.

- Medical materials such as biodegradable dressings or bandages.

- Components for batteries and energy storage devices.

In addition, the process is energy efficient, does not rely on fossil resources and is based on bacterial cultures that can be scaled up without harming the environment.

This development not only represents a milestone in materials science, but could become a real tool for transforming our relationship with plastics and moving towards a truly circular and sustainable economy.