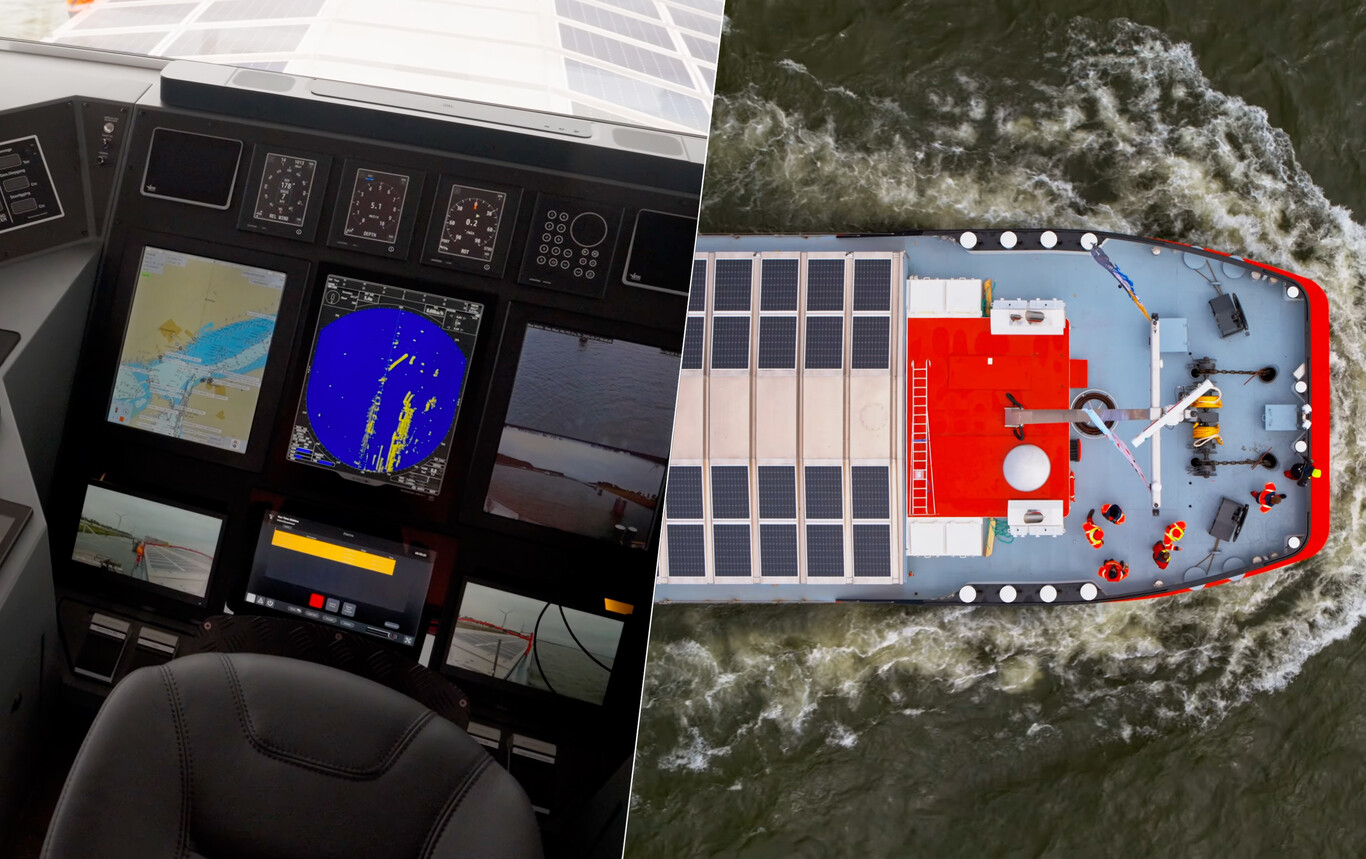

Covered by 192 solar panels, Blue Marlin looks more like a floating installation than a traditional cargo ship. But beneath its futuristic appearance lies a remarkable advance: this ship, designed to operate in inland waters, is the first of its kind capable of using solar energy to propel itself. We’re not talking about auxiliary systems or on-board lighting: the panels power its electric propulsion system. And best of all, it’s already sailing.

The technical breakthrough isn’t just in the design: it’s in how it moves. The Blue Marlin combines solar energy, batteries and diesel generators in a hybrid system capable of adapting to each stage of the journey. In good light conditions, the panels can generate up to 35 kilowatts, enough to power the propulsion system without external assistance. At other times, what is known as peak shaving comes into play: an automatic management system that reduces the use of generators, activating them only when really necessary.

Solar panels, batteries and diesel: all at the service of a specific task

Solar energy has already played a leading role in other maritime projects: from cruise ships installing panels on balconies to flexible sails with perovskites that promise a new generation of sustainable boats. More than a decade ago, someone even dared to sail around the world in the largest solar-powered boat ever built.

Blue Marlin was not created to sail around the world or cross oceans. Its objective is much more specific: to transport steel and bulk cargo in north-western Germany. These types of routes, which pass through inland canals, are key to reducing truck use and emissions in the logistics chain. By incorporating electric propulsion, they claim, Blue Marlin can reduce CO2 emissions by up to 36,000 kilos per year, a significant figure for a single boat.

In addition to its hybrid propulsion system, the Blue Marlin incorporates a second equally important innovation: remote navigation. Thanks to SEAFAR technology, the ship can operate without a crew on board for certain sections of the journey. After successfully passing tests, the German authorities have authorised the Blue Marlin to sail remotely between Salzgitter and Friedrichsfeld. This not only reduces operating costs, but also opens the door to a new logistics model in which part of the control can be carried out from land.

One of the biggest challenges in river transport is maintaining operability when water levels drop. The Blue Marlin was built with this problem in mind. Its hull has been designed to ensure stability and manoeuvrability with a draught of only 1.10 metres. Thanks to its Veth rudder propellers and an additional bow thruster, it can manoeuvre with precision even in complex sections. This capability makes it a robust tool for an increasingly unpredictable environment.

Behind the Blue Marlin are two key players: HGK Shipping, which moves 43 million tonnes a year in Europe, and Salzgitter AG, responsible for one of the largest steel productions on the continent. Together, they have developed a cargo ship that not only fulfils a logistical function but also symbolises a change of course. Construction has been carried out in several phases and countries, with very demanding standards.